Views: 0 Author: Site Editor Publish Time: 2025-08-11 Origin: Site

Aluminum composite panels usually weigh about 2.5 pounds for each square foot. A regular 4'x8' panel weighs close to 80 pounds.

These panels are light. This helps workers install them faster. It also makes labor cheaper.

Because they are light, moving them is easier. Trucks use less fuel, which is better for the planet.

You can recycle aluminum composite panels. This helps builders use green methods.

Material Type | Transportation Emissions | Production Impact |

|---|---|---|

Aluminum Composite Panels | Lower because they are light | High because making them uses a lot of energy |

Heavier Materials | Higher because they weigh more | Lower when making them |

Aluminum composite panels weigh around 2.5 pounds for each square foot, so they are light and simple to put up. - Picking lighter panels lowers shipping costs and helps the environment because trucks burn less fuel. - Recycling aluminum composite panels helps green building and cuts down on trash. - The thickness of a panel changes its weight; thin panels are easier to move, but thick panels are stronger. - Use the given weight formulas to figure out how much your panels will weigh for your project.

Aluminum composite panels are used in many buildings. These panels usually weigh between 2.5 and 4.5 pounds for each square foot. You can look at the table below to see some common weights:

Product Type | Weight (lbs/ft²) |

|---|---|

Alumanate Aluminum Composite Panels | About 2.5 |

regular 4'x8' acm panel with 4mm thickness weighs from 32 to 55 pounds. The weight depends on how thick the panel is and what the core is made of. Goodsense makes acm panels with a safe polyethylene core and two aluminum sheets. These layers make the panels light and simple to move. You can use acm panels for walls, signs, and inside decorations. Their light weight helps you put them up fast and saves money on shipping. Choosing aluminum composite material from Goodsense also helps the environment.

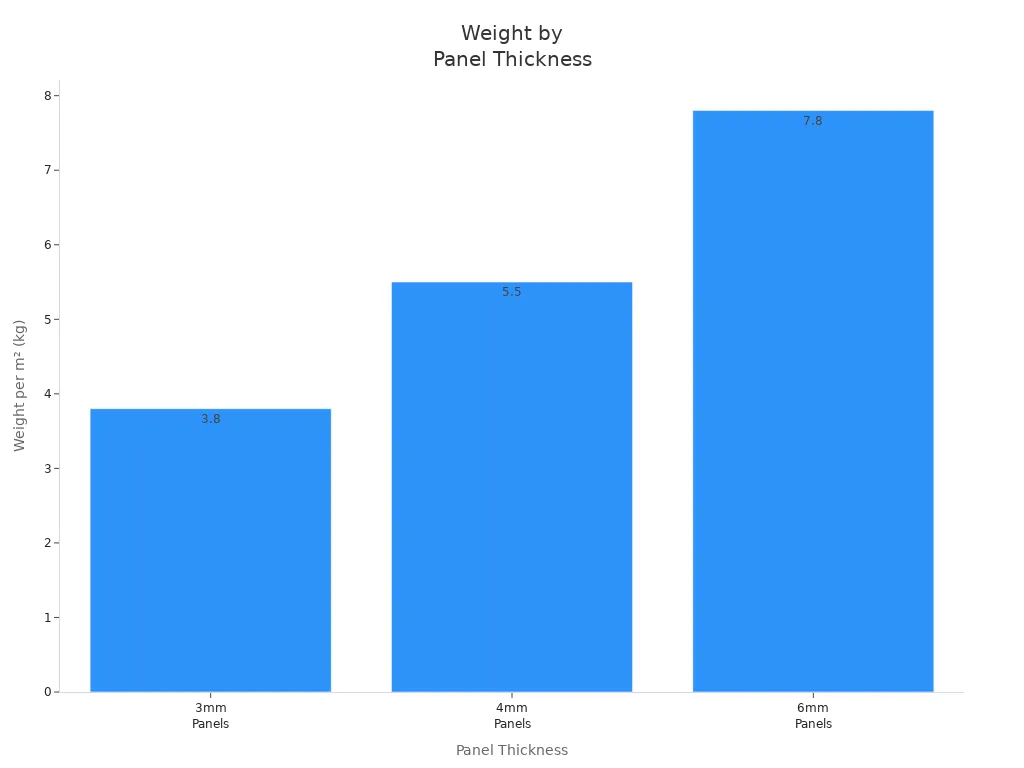

You can pick acm panels in different thicknesses. The most popular thicknesses are 3mm and 4mm. You can also find 1mm, 1.5mm, 2mm, and 5mm panels. The thickness of the aluminum composite panel changes how much it weighs. Here is a short list to help you compare:

3mm thickness: about 2.5 pounds per square foot

4mm thickness: about 1.25 pounds per square foot

6mm thickness: heavier than 4mm panels

Thicker panels have more material and weigh more. Thicker acm panels are stronger and can handle more bumps. Remember, the weight of composite panels goes up when the thickness increases. Goodsense acm panels use a safe polyethylene core and aluminum layers to keep the weight low and help stop fires. You can count on these aluminum composite material products for safe and green building.

Tip: Always keep acm panels flat. Do not put heavy things on them. This stops dents and scratches and keeps your aluminum composite panels looking good.

There are many core materials in acm panels. The core changes how heavy and strong the panel is. Some common cores are balsa, honeycomb, PVC foam, and polyurethane foam. Each core has its own features. Look at the table below to compare them:

Core Material | Characteristics | Weight Influence |

|---|---|---|

Balsa | Has a closed-cell structure with long cells. | Very light, good for flat and curved panels. |

Honeycomb | Made from paper or aluminum, density can change. | Some types are very light. |

PVC Foam | Mix of PVC copolymer and stabilizers, density from 4 to 30 lbs/ft³. | Strong but not heavy. |

Polyurethane Foam | Comes in many shapes, stays strong when hot. | Works for many uses. |

Goodsense acm panels use light and recyclable materials. Picking these panels helps the planet. Many acm panels use aluminum, which is lighter than steel. Honeycomb acm panels have a hexagon cell shape. This makes them strong and light. You get panels that last longer and weigh less.

Modern fire-resistant aluminum cladding uses cores that do not burn or stay stable in heat. These cores help stop fires from spreading.

Using acm panels also helps green building. The recyclable parts save energy and cut down on waste.

The thickness of acm panels changes their weight. You can choose panels from 2mm to 8mm thick. Most acm panels are 4mm thick. See the table below to learn how thickness changes weight:

Panel Thickness (mm) | Weight (kg/sqm) |

|---|---|

4mm | 5.5kg/sqm |

2mm-8mm | Weight goes up as thickness increases |

Thicker acm panels are heavier. They are also stronger. Thin acm panels are lighter and easier to move. Check the thickness before you pick acm panels for your job.

The size of acm panels affects how much they weigh. You find the area by multiplying length and width. For example, a standard acm panel that is 125×320 cm covers 4 square meters. Bigger panels weigh more because they use more material. Large acm panels can make installation faster because you need fewer seams and fasteners.

The weight of acm panels is about 5.5 kg per square meter.

Bigger panels might cost more but save time when installing.

The size you pick changes both material and labor costs.

Always think about thickness, core, and size when choosing acm panels. Goodsense acm panels are light, recyclable, and help you build safely and in a green way.

You can figure out how much acm panels weigh with a simple formula. First, measure the length and width to get the area. Next, multiply the area by the weight for each square foot or meter. Here are the formulas you can use:

Weight (lbs) = Length (ft) × Width (ft) × Weight per Square Foot (lbs/sq ft)

Weight (kg) = Length (m) × Width (m) × Weight per Square Meter (kg/m²)

You can also use volume and density to get a more exact answer:

Volume = Length × Width × Thickness

Weight = Volume × Density (acm panels are about 1.4 g/cm³)

These formulas help you guess the weight for both regular and special sizes. The number you get is an estimate. The real weight might be different because of how the panels are made.

Let’s see some examples with aluminum composite panel sizes:

For a 4'x8' acm panel that weighs 3.5 lbs/sq ft:

Weight = 4 × 8 × 3.5 = 112 lbs

For a 4'x8' acm panel that weighs 7.5 kg/m² and is 1.22m × 2.44m:

Weight = 1.22 × 2.44 × 7.5 ≈ 22.3 kg

For a 5'x10' acm panel that weighs 4 lbs/sq ft:

Weight = 5 × 10 × 4 = 200 lbs

If you want to use volume and density for a panel that is 2m × 1m × 4mm:

Volume = 2 × 1 × 0.004 = 0.008 m³

Weight = 0.008 × 1400 = 11.2 kg

These examples show how you can use aluminum composite panel sizes to guess the weight for any acm panels you need.

You can find acm panels in many regular sizes. The most common aluminum composite panel sizes are:

Panel Thickness | Panel Sizes | Dimensions |

|---|---|---|

3mm to 6mm | Custom sizes available | Usually 4ft x 8ft panels |

Thickness | Description |

|---|---|

3mm | Used for many different things |

4mm | Good for flexible designs |

6mm | Works for lots of uses |

You can order special sizes for unique projects. Use the same formulas to figure out the weight for any aluminum composite panel size you pick.

Light acm panels are good for the environment:

You use less energy to move acm panels because they are lighter than stone or concrete.

Many companies use recycled aluminum and low-VOC coatings in acm panels.

Energy-saving ways to make panels help the planet.

Aluminum composite panels help buildings save energy and support green building.

Picking acm panels with recyclable cores and earth-friendly coatings helps you build in a smart way and care for the planet.

You want to choose the right acm panels for your project. You need to know how much each panel weighs. The weight depends on the thickness and size. You can use the table below to compare popular acm panel sizes and thicknesses. This helps you plan for installation, transport, and support.

Panel Size (mm) | Thickness (mm) | Area (m²) | Weight per m² (kg) | Total Weight (kg) |

|---|---|---|---|---|

1220 x 2440 | 3 | 2.98 | 3.8 | 11.3 |

1220 x 2440 | 4 | 2.98 | 5.5 | 16.4 |

1220 x 2440 | 6 | 2.98 | 7.8 | 23.2 |

1500 x 3000 | 4 | 4.5 | 5.5 | 24.8 |

1500 x 3000 | 6 | 4.5 | 7.8 | 35.1 |

You can see that thicker acm panels weigh more. Larger panels also add to the total weight. Always check these numbers before you order acm panels for your building or sign project.

Alt text: Bar chart showing weight per square meter for acm panels with 3mm, 4mm, and 6mm thicknesses

You may wonder how acm panels compare to other cladding materials. The table below shows the difference in weight. You can see that acm panels are lighter than solid aluminum or steel panels. This makes acm panels easier to handle and install.

Material Type | Weight Comparison |

|---|---|

Solid Aluminum Cladding | Heavier |

acm Panels | Lighter |

Steel Cladding | Heavy; needs strong support |

Aluminum Cladding | Lightweight; easy to handle |

You can use acm panels for many jobs. You save time and money because they are light. You also help the environment by choosing acm panels. Goodsense acm panels give you strong, safe, and green options for your next project.

Tip: Always check the weight table before you buy acm panels. This helps you pick the right thickness and size for your needs.

You now know that aluminum composite panels are lightweight, strong, and easy to handle. The weight depends on thickness, core material, and panel size. To pick the right panel, think about your project needs. For signs, choose thinner panels. For cladding, select thicker ones.

Use the weight formula and tables in this guide to plan your next project with confidence.

First, measure the length and width of the panel. Next, multiply these numbers together. Then, multiply that answer by the weight for each square foot or meter.

Goodsense makes panels as thin as 1mm. These thin panels weigh less than thicker ones. They are good for indoor signs and displays.

Thin panels are simple to carry and put up.

Yes, you can recycle Goodsense aluminum composite panels. Both the aluminum and polyethylene core can be recycled.

Recycling helps builders use green building methods.

Thicker panels have more material, so they are heavier.

Thickness (mm) | Weight per m² (kg) |

|---|---|

3 | 3.8 |

4 | 5.5 |

6 | 7.8 |

Light panels make installation quick and safe. You need fewer workers and less equipment.

Picking lightweight Goodsense panels saves time and money.